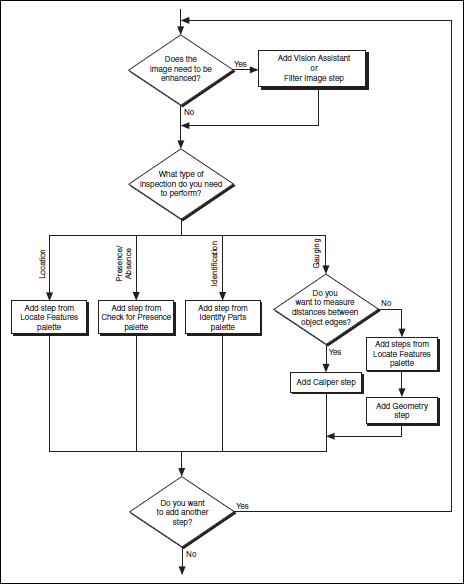

Creating a New Inspection

Select File»New. Vision Builder AI opens a new, blank

inspection.

Acquiring Inspection Images

In the Inspection Steps palette, the Acquire Images

tab contains several

acquisition steps you can use to acquire images from

many different types

of cameras. The tab also contains a Simulate

Acquisition step, which

simulates image acquisition by loading images from

file. The Select Image

step enables you to switch to a previously acquired

image that you need to

process later in the inspection.

Defining a Feature on which to Base aCoordinate System

In a machine vision inspection, you typically limit your inspection and processing to a region of interest (ROI) rather than the entire image for the following reasons:

• To improve your inspection results by avoiding

extraneous objects

• To increase inspection speed

To limit the inspection area, the parts of the object

you are interested in

must always be inside the ROI you define.

If the object under inspection is fixtured and always

appears at the same

location and orientation in the images you need to

process, defining an ROI

is straightforward. However, if the object under

inspection appears shifted

or rotated within the images, the regions of interest

need to shift and rotate

with the object under inspection.

For the regions of interest to move in relation to the

object, you need to set

a coordinate system relative to a significant and

original feature of the

object under inspection. Choose a feature that is

always in the field of view

of the camera despite the different locations that the

objects may appear in

from image to image. Also, make sure the feature is

not affected by major

defects that could drastically modify the visual

appearance of the feature.

Here we configure a Match Pattern step that

locates a bottle feature on which you can base a

coordinate system.

1. In the Inspection Steps palette, select the Locate

Features tab.

2. Click the Match Pattern step. The NI Vision

Template Editor opens.

3. Draw a rectangle around the base of the sprayer, as

shown in

The picture. This region becomes the pattern matching

template.

4. Click Next.

5. Click Finish to accept the template.

6. On the Main tab, enter Locate Sprayer Base in the

Step Name

control.

7. Redraw or decrease the default green ROI so that it surrounds only the

lower portion of the image, as shown in the picture.

8. On the Template tab, drag the red crosshair mark in the template

image to the left edge of the sprayer base, as shown in the picture. This

changes the focal point of the template.

9. The focal point indicates the part of the template that you want to

return as the match location. By default, the focal point is the center of

the template. You can modify the focal point by moving the red

crosshair or by specifying a Match Offset. Later in this inspection,

you use the match location as the origin of a coordinate system.

10. On the Settings tab, set Number of Matches to Find to 1.

11. On the Limits tab, enable the Minimum Number of Matches control,

and set the value to 1.

12. Click OK to add the step to the inspection.

Checking for the Cap Using Measure Intensity

The image of the spray bottle was acquired using a backlight. The cap

appears dark on the bright background. Complete the following

instructions to configure a Measure Intensity step to check for the

presence of a spray bottle cap.

1. In the Inspection Steps palette, select the Check for Presence tab.

2. Click the Measure Intensity step. The property page for the step

opens.

3. On the Main tab, enter Check Cap Presence in the Step Name

control.

4. Enable the Reposition Region of Interest control.

Enabling this control allows you to link the regions of interest specified

in this step to a previously defined coordinate system so that

Vision Builder AI can adjust the location and orientation of the ROI

from image to image relative to the specified coordinate system.

The Reference Coordinate System list shows all the previously

defined coordinate systems. Coordinate System is the default

reference coordinate system because it is the only Set Coordinate

System step in the current inspection.

Notice that the Measure Intensity step supports a variety of different tools

that enable you to draw different shaped regions of interest, such as a point,

line, broken line, freehand line, rectangle, ellipse, annulus, polygon, and

freehand region. These tools are available in the main menu bar.

5. Using the default Rectangle Tool, hold down the <Ctrl> key, and draw

three regions of interest that enclose edges of the cap, as shown in

the picture. Pressing the <Ctrl> key enables you to draw multiple

regions of interest for the step.

6. Click the Limits tab.

At the bottom of the tabbed page, Vision Builder AI returns the

intensity statistics of the pixels inside the regions of interest. Pixel

intensities can range from 0–255, where 0 equals black and 255 equals

white.

The Minimum Intensity value at the bottom of the page returns the

lowest pixel value inside the regions of interest. The backlit edges of

the plastic cap appear in silhouette as dark pixels (which have low pixel

intensities) on a bright background (which has high pixel intensities).

Therefore, when the cap is present, the minimum intensity for the

regions is low. When the cap is not present, the minimum intensity for

the regions is high because the regions contain only bright background

pixels.

7. Enable the Minimum Intensity control. Set the Maximum value

to 50.00.

8. Click OK to add the step to the inspection.

9. Click the Run State Once button located in the State Configuration

window.